en

en en

enAerospace

Automotive

HVAC (Heating, Ventilation, Air Conditioning)

Fan and Air Condition

Lighting and Building

Kitchenware

Agricultural

Steel Pipe for Oil & Gas

Shipbuilding

Wind Towers

Medical and Chemical

Dish Head

Shear spinning, also known as forced spinning of conical components, involves mounting and securing a sheet or conical blank onto a die. During spinning, the spinning roller, along with the workpiece and die, rotates, causing the workpiece to deform incrementally. This process allows the blank to achieve the desired wall thickness and angle. Shear spinning is further categorized into two types: forward spinning and reverse spinning.

In shear spinning, the wall thickness of conical or other uniquely shaped parts adheres to the Law of Sines. The process typically involves single or double roller passes, deliberately reducing wall thickness without altering the diameter. Discussions on forming load and accuracy across different stages of the process have been conducted, leading to the development of an optimal forming scheme based on analytical insights.

The CNC spinning flanging machine is a specialized machine designed for the flanging of air ducts in the fan industry. It is primarily used for the automated flanging, punching, and reinforcing edge pressing of various components such as in......

Our CNC metal spinning machines come in 20 different models. The machines’ mechanics, electrical and software are identical from model to model, the difference between the models are slide size and machine travel and number of rollers. The......

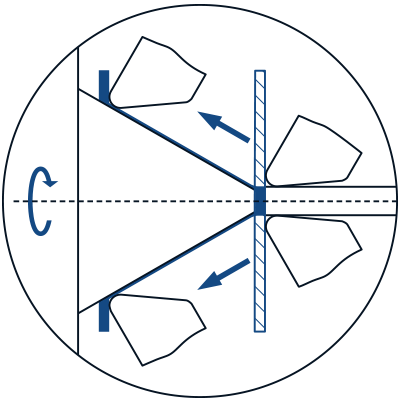

Three rollers spinning machine are mainly used for the spinning of the reducing or thickening of the tubes; Small diameter of the thick materials and could harden some surface by spinning The machine has the advantages of high rigidity and ......

CNC Hot spinning machine featuring Siemens CNC, automatic lubrication and heating system is specially designed for high pressure cylinders (lpg, fire extinguishers & gas etc), pressure vessels, and nd closing & neck forming of high pressure......