en

en en

enAerospace

Automotive

HVAC (Heating, Ventilation, Air Conditioning)

Fan and Air Condition

Lighting and Building

Kitchenware

Agricultural

Steel Pipe for Oil & Gas

Shipbuilding

Wind Towers

Medical and Chemical

Dish Head

Spinning seamless integral cylinders represent a novel process and product in the industry. These cylinders come in four main types: steel seamless gas cylinders, aluminum alloy gas cylinders, composite cylinders with steel inner walls, and composite cylinders with aluminum inner walls. They are primarily used in breathing gas cylinders, CNG natural gas cylinders, and for transporting medium to large volumes of high-pressure gases.

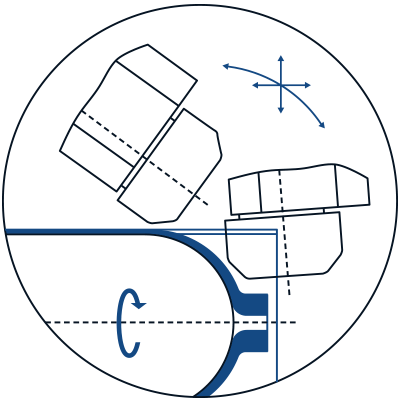

The manufacturing process for seamless integral gas cylinders varies according to the material used. For aluminum alloy gas cylinders, typically made from 6061 aluminum plate or bar, the process involves plate stamping followed by heating the aluminum ingot. This is followed by back-extrusion into a cup shape, strong rotation to create the straight wall sections, and then hot closing to form the bottle shoulder and neck. In contrast, steel cylinders, usually made from 30CrMo, undergo hot spinning of tubular sections back covering, strong rotation for straight wall sections (or non-rotation), hot closing (900°C to 1000°C), and universal spinning to shape the bottle shoulder and neck.

Our CNC metal spinning machines come in 20 different models. The machines’ mechanics, electrical and software are identical from model to model, the difference between the models are slide size and machine travel and number of rollers. The......

CNC Hot spinning machine featuring Siemens CNC, automatic lubrication and heating system is specially designed for high pressure cylinders (lpg, fire extinguishers & gas etc), pressure vessels, and nd closing & neck forming of high pressure......