en

en en

enAerospace

Automotive

HVAC (Heating, Ventilation, Air Conditioning)

Fan and Air Condition

Lighting and Building

Kitchenware

Agricultural

Steel Pipe for Oil & Gas

Shipbuilding

Wind Towers

Medical and Chemical

Dish Head

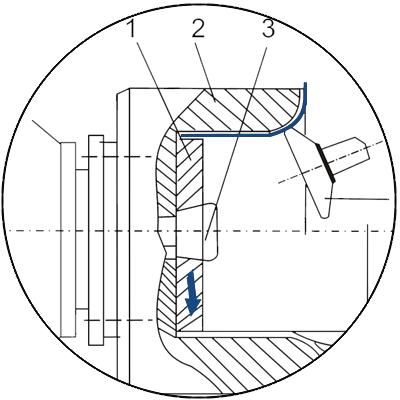

Double wheel spinning flanging is a technique used for creating flanges and shaping the bells of cylindrical products. This process involves securing the edge of cylindrical shaped items with two rollers as well as punching of flange holes. By applying a precise angle and rotational clamping force, cylindrical products can be shaped with flanges at 90 degrees or other specific angles. Subsequently, a turning tool is used for trimming, ensuring a flawless outline. For successful spinning flanging, it is crucial to maintain the material quality, particularly in terms of the cylindrical shape's ovality and the welding integrity, as these factors significantly influence the stability and quality of the clamping.

This equipment is capable of processing ducts, cones, and plates made of steel up to 16mm thick. It's perfectly suited for producing components for both axial and centrifugal fans, including fan casings, impeller casings, inlet bells, inlet cones, shrouds, bell mouths, and flanges. Additionally, it offers the functionality for precise punching of flange holes

Our optimized model is specifically designed to create high-quality flanges and reinforced flanges with punched holes, bell mouth, and inlet cones on cylindrical ducts. This makes it the perfect choice for manufacturing axial fan casings. O......

Our most advanced and versatile model can handle both ducts and plates up to 25mm thick, making it perfect for producing parts for both axial and centrifugal fans. Our machine is capable of handling various parts such as fan casing, impelle......

The CNC spinning flanging machine is a specialized machine designed for the flanging of air ducts in the fan industry. It is primarily used for the automated flanging, punching, and reinforcing edge pressing of various components such as in......

Our CNC metal spinning machines come in 20 different models. The machines’ mechanics, electrical and software are identical from model to model, the difference between the models are slide size and machine travel and number of rollers. The......

CJ offers the most extensive range of dished head flanging machines available in the global market. These machines have the capability to enhance production quality while reducing costs. Our automatic dished end flanging machine are cons......

Tank dished end flanging machine is designed for blanking and spinning heads and baffles for liquid tankers of various shapes. It comes in two versions: one with a die and one without. Powered by a hydraulic motor, it offers precise pres......

We build machines specifically designed for every specific application that our customer needs. All our machines are built after a deep analysis of the customer's needs making possible to incorporate all the features and accessories require......

The machines is specially design for the ventilation industry especially for large diameter. they are suitable for processing of the components for ventilation, modular chimneys, flanging, beading, marking of several pieces This series o......

Our customized vertical flanging machine is expertly engineered to meet the specific demands of flange fan production. Designed for precise flanging and punching, this machine utilizes servo-driven adjustments to ensure consistent accuracy ......