en

en en

enAerospace

Automotive

HVAC (Heating, Ventilation, Air Conditioning)

Fan and Air Condition

Lighting and Building

Kitchenware

Agricultural

Steel Pipe for Oil & Gas

Shipbuilding

Wind Towers

Medical and Chemical

Dish Head

Expanding diameter spinning is a spinning forming method in which a hollow rotating body container or a tubular blank is increased in diameter (middle or end) by a spinning tool. The limitation of this method is mainly the material properties of the workpiece, such as tensile strength. Strength, yield limit, elongation rate, section shrinkage rate, etc.; depending on the degree of expansion of the workpiece, it is often divided into several passes. The stress during the molding process cannot exceed the tensile strength of the material, otherwise it will cause cracking. If the material has a large tendency of work hardening, the number of passes should be less, and the amount of expansion per pass should be as large as possible. Otherwise, due to severe hardening, intermediate heat treatment needs to be performed earlier, otherwise it cannot be carried out;

Our optimized model is specifically designed to create high-quality flanges and reinforced flanges with punched holes, bell mouth, and inlet cones on cylindrical ducts. This makes it the perfect choice for manufacturing axial fan casings. O......

Our most advanced and versatile model can handle both ducts and plates up to 25mm thick, making it perfect for producing parts for both axial and centrifugal fans. Our machine is capable of handling various parts such as fan casing, impelle......

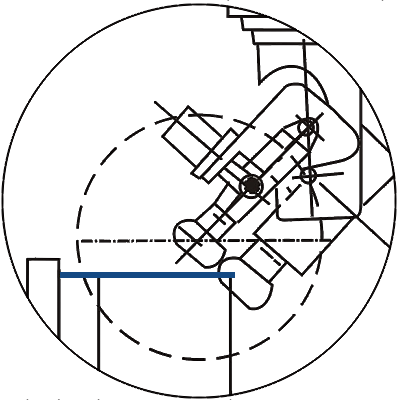

Our CNC metal spinning machines come in 20 different models. The machines’ mechanics, electrical and software are identical from model to model, the difference between the models are slide size and machine travel and number of rollers. The......

Three rollers spinning machine are mainly used for the spinning of the reducing or thickening of the tubes; Small diameter of the thick materials and could harden some surface by spinning The machine has the advantages of high rigidity and ......